Greetings All,

Working With Wood Loads

I've always believed that nothing looks like wood except wood. I know there are modelers who can take styrene and make convincing wood loads from it however I my attempts at this leave me with styrene pretending to be wood.

With this in mind I asked for and received two packages of wood stirrers as Christmas presents to hopefully use as lumber loads.

Two thousand wood stirrers are supplemented by some Woodpile wood shapes that I thought would make some nice open car loads along with two packages of strip wood for bracing. Two thousand!! What was I thinking!!!

The wood cubes fit onto the Rock Island bulkhead flat and have some potential.

Eight cubes to package could give me three open car loads.

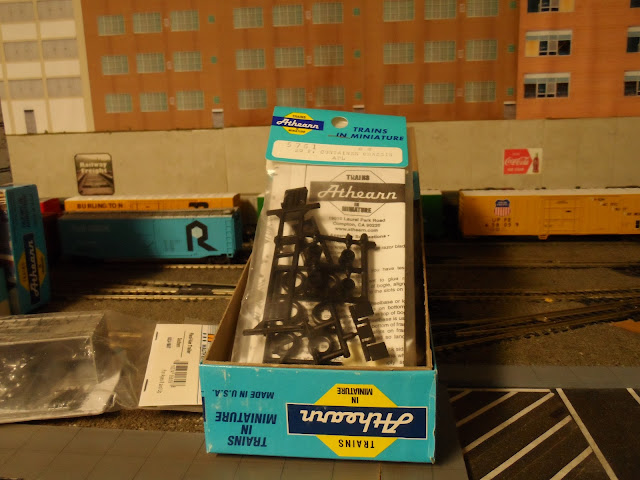

From a big box hobby store came these rectangular shapes.

Probably too big for plywood loads but has potential as sheet steel loads.

Dollar Store blocks will get protected by a wood crate to make a High & Wide Load.

The crate is under construction.

The two end cubes are being dressed up with the coffee stirrers to simulate a board by board crate. This was very time consuming and these will be the last of the board by board crates in this project.

The High & Wide crate is complete and fits nicely on the longer CNW depressed center flatcar. Some blocking is still needed.

The first coffee stirrer lumber load is being being built. This has potential.

The now completed lumber load rides on an MDW Boise Cascade bulk head flat.

Not too bad. Needs some weathering and maybe some banding and paint on the ends of the lumber. The bracing is constructed to fit into the shallow stake pockets of the 67' Atlas bulkhead flats in my fleet.

The two large crates ride into Terminal Yard on APRR bulkhead flatcar #166941.

A three crate load rests on an ACL bulkhead flat as the glue dries. Still needs some bracing. This car has open stake pockets which makes securing the load pretty easy.

The wood cubes fit onto the Rock Island bulkhead flat and have some potential.

Eight cubes to package could give me three open car loads.

From a big box hobby store came these rectangular shapes.

Probably too big for plywood loads but has potential as sheet steel loads.

Dollar Store blocks will get protected by a wood crate to make a High & Wide Load.

The crate is under construction.

The two end cubes are being dressed up with the coffee stirrers to simulate a board by board crate. This was very time consuming and these will be the last of the board by board crates in this project.

The High & Wide crate is complete and fits nicely on the longer CNW depressed center flatcar. Some blocking is still needed.

The H&W crate fits perfectly within the width of the flatcar eliminating some of the troublesome wide of the H&W.

Three cubes with the coffee stirrers cut to fit the ends to create a plywood and dimensional lumber built crate. Much easier to build and much faster. The first coffee stirrer lumber load is being being built. This has potential.

The now completed lumber load rides on an MDW Boise Cascade bulk head flat.

Not too bad. Needs some weathering and maybe some banding and paint on the ends of the lumber. The bracing is constructed to fit into the shallow stake pockets of the 67' Atlas bulkhead flats in my fleet.

The two large crates ride into Terminal Yard on APRR bulkhead flatcar #166941.

A three crate load rests on an ACL bulkhead flat as the glue dries. Still needs some bracing. This car has open stake pockets which makes securing the load pretty easy.

Friday was bracing day and the three crate load atop the ACL bulkhead is ready to go. The load and bracing are built to fit the stake pockets on this car and two others made by Con-Cor.

The board by board crates are braced and ready. The load fits this Walther's car and will maybe fit on a few others.

Final Thoughts and Comments

There are a couple of downsides to wood loads like the amount of time it takes to build a lumber load out of coffee stirrers. The strips are not exactly straight which gives them a prototype appearance but slows down the build and once one level is glued it has to be weighted down until the glue dries.

The second issue I'm having is that not all of the bulkhead flatcars have open stake pockets making the securing of the loads challenging. I want to keep the loads within the width of the car as much as possible. Drilling thru faux pockets isn't an option due to how the car is constructed.

Last but not least if it ever stops raining here I can open up the Patti O Paint Shop and get these loads weathered.

Thanks for reading!!!

See you soon!!!